|

Next Meeting February, 2009

Howard County Senior Center

9401 Frederick Road

Ellicott City, Maryland

410 313 1400

7:30 PM.

Have dinner with us before the meeting

Double T Diner

10055 Baltimore National Pike,

Ellicott City, MD 21042

410

750 3300

6 to 6:30pm. Tell them to seat you with the Watch &

Clock Group.

************************************

Club Officers

Board Members

******************************************************

Meeting/Workshop Activity

Watch Related Lecture with Bob Rothen & Stan Craig

*******************************

Tech Question for the next meeting:

If you have a bushing that is installed incorrectly causing depthing problems, how would you correct this

situation?

Below in our Tech Column is an interesting solution with a milling machine.

*******************************

From the Pres.

Thanks to George Tresansky and Bob Rothen for doing our January 12 Metal Bluing Lecture & Workshop. Interesting process

that can be done by anyone.

Not to mention the Lantern Pinion Repair at the January 26 workshop by yours truly.

I have included a Renewal/Application for 2009, bring it to the next meeting, we need you to renew for 2009.

Want to have a Mart at our meetings? Bring anything you have to the next Meeting.

************************************

Meeting Minutes

(Thanks to LeRoy Roberts)

HAM 12 January 2008 Meeting Minutes

In attendance were: Wilbur

Robinson, John Ryea, Leroy Roberts, Earl Knight, Bob Rothen, Jack Kennan, Dan Spath, John Kuntz, George Tresansky, Brett Louis,

George Painter, David Grau, Al Takatsch, Jack Bishop and Bill Miller.

Al opened the meeting asking each person

to introduce themselves and share their current project or a resent accomplishment. This was informative

with many interesting personal comments shared.

Treasures Report: None

provided.

Secretary Report: Dues

are due.

Old Business: Al inquired

as to how long the HAM News Letter should be provided to persons who have not renewed their membership. The

news letter is provided via e-mail. The consensus was since it cost nothing to send the letter we should

continue to provide it. Doing so may entice past members to return. Also, we need to

continue to send it to persons with life time membership so as not to cut them off from the club.

Brief discussion about whether or not the

‘safety sheets’ were available for members to read and sign. They were not.

New Business:

Al plans to set up a Buy Sell Trade Listing.

Al felt it should be for club members only and therefore separate from our public web page. He will

send the listing via an e-mail once a month.

The presidents e-mail reminder for our

meeting contained a request for information on correcting pendulum wobble. Members shared past experiences

with pendulum, crutch and suspension spring faults. A ‘pendulum wobble faults’

check list downloaded from the NAWCC was shared.

The door prize was won by Earl Knight.

Bob Rothen and George Tresansky provided

a technical discussion and demonstration on metal bluing. George furnished metal samples for

members to polish and blue. He stressed the importance of ensuring complete (intimate) contact between

the item being blued and the medium conducting the heat. George used brass filings on a heavy brass plate

in his demo. Other members offered that glass beads or sand would also work. Thanks

to Bob and George for their informative demonstration.

Our nest meeting is scheduled for January

26th at the Howard County Senior Center .

Respectfully submitted,

LeRoy Roberts

*************************

Tech Column

How to correct a bushing that is off center using a Milling Machine

Great question to a more common problem than one would think, but seldom discussed.

Personally

I avoid this problem by bushing with a small Milling Machine. For those who are frugal, I think you would find a small mill

less expensive and more efficient than the many tools it replaces including bushing machines.

In this case it is highly

efficient in correcting manufacturing errors or poor quality bushing work.

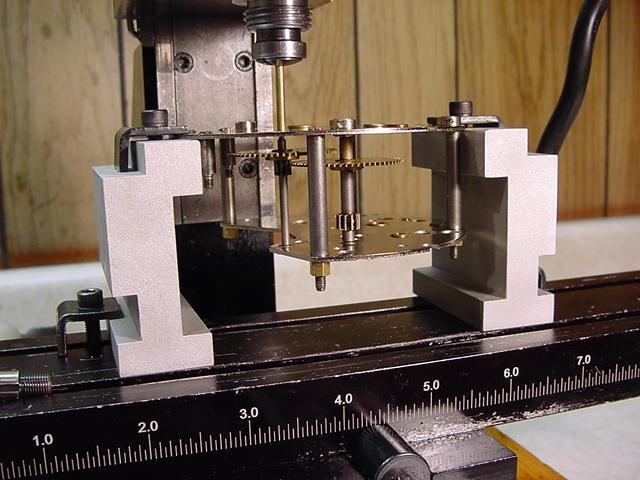

To correct such a problem I first remove

the old bushing. Next the arbor/pinion/wheel are installed along with the previous or next wheel between the plates. The movement

is then installed in a movement holder and mounted in the Mill as shown in the attached Photo. From this point a piece of

bushing wire is installed in the spindle and dropped over the pivot of the incorrect bushing. This allows the pivot to be

very precisely located within the bushing hole with the slides until correct depthing is achieved. When spinning the two wheels

for correct depthing, you will be very surprised at how much difference a slight movement of the pivot will make on friction

free operation.

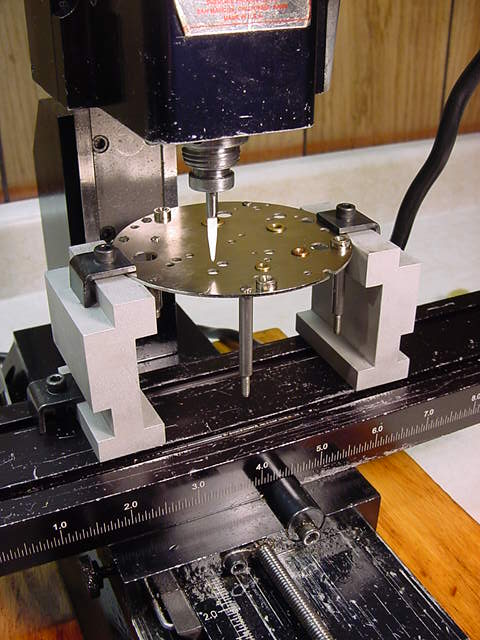

Once depthing has been achieved the bushing wire is removed and the next larger size bushing reamer

is installed in the Mill spindle. Then the lower plate is removed for reaming/boring a new bushing hole. The movement holder

is designed to hold the top plate only and allow removal of the lower pate (See Attached Photo) Because the mill and movement

holder are very rigid the reamer will bore the new bushing hole in the correct depthed locatation rather than ream the hole.

Personally I found this to be a fast, efficient and highly effective repair with a quality appearance.

Jerry

Kieffer

.

Need Watch & Clock Parts or Tools?

Click Here

|